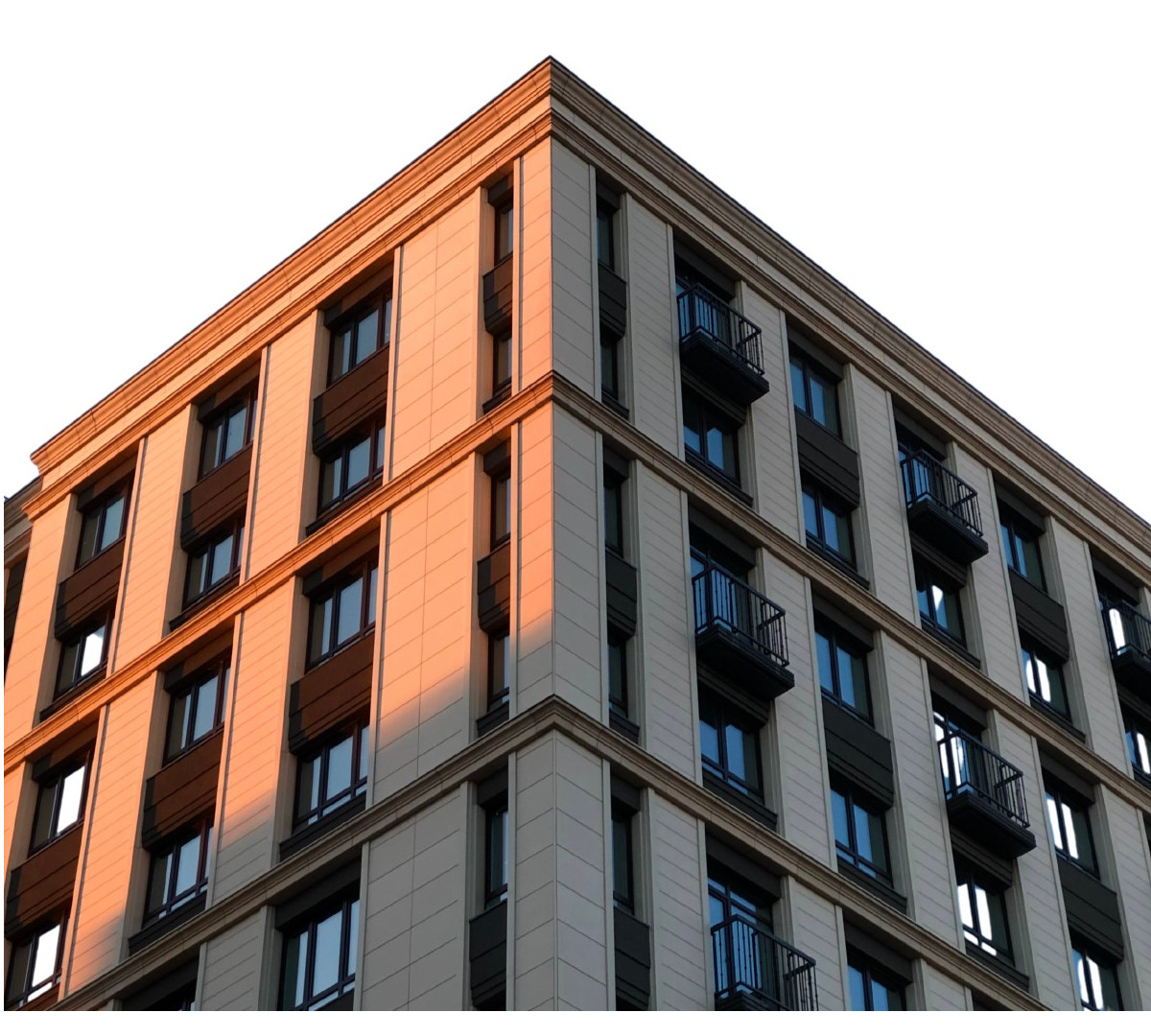

i. Demand Forecasting in building materials industry

Demand forecasting plays a crucial role in the building material industry due to the long lead times associated with manufacturing and distribution, as well as the significant investment in inventory and production capacity. By accurately forecasting demand, stakeholders can optimize inventory levels, production schedules and supply chain operations to meet customer needs while minimizing excess inventory, stockouts and production bottlenecks. Demand forecasting in the building materials industry presents several challenges due to the complexity of factors influencing demand and the dynamic nature of the construction market. Some of the key challenges include:

Long Lead Times and Production Cycles

Building materials often have long lead times for manufacturing, transportation and delivery, which can complicate demand forecasting efforts. Variability in lead times and production cycles can introduce uncertainty into demand forecasts.

Complex Supply Chain Dynamics

Supply chain disruptions, such as raw material shortages, transportation delays or production bottlenecks, can impact the availability and cost of building materials and affect demand forecasts. Managing supply chain risks and ensuring continuity of supply is critical for accurate demand forecasting.

Limited Historical Data and Forecast Accuracy

Limited historical data or inconsistent data quality can make it difficult to develop accurate demand forecasts, particularly for new or innovative products. Forecast accuracy may be further compromised by factors such as product seasonality, market fluctuations and unforeseen events.

Volatility in Construction Market

The building materials industry is closely tied to the construction market, which can be highly volatile due to economic fluctuations, regulatory changes, and geopolitical factors. Predicting demand accurately in such a volatile market environment can be challenging, as demand for building materials is sensitive to changes in construction activity, infrastructure projects, and housing market conditions

Addressing these challenges requires a combination of advanced forecasting techniques, data analytics, market intelligence and collaboration across the supply chain. By leveraging technology, predictive analytics, and industry expertise, stakeholders in the building materials industry can improve the accuracy of demandforecasts, optimize inventory management, and enhance operational efficiency to meet customer needs effectively.

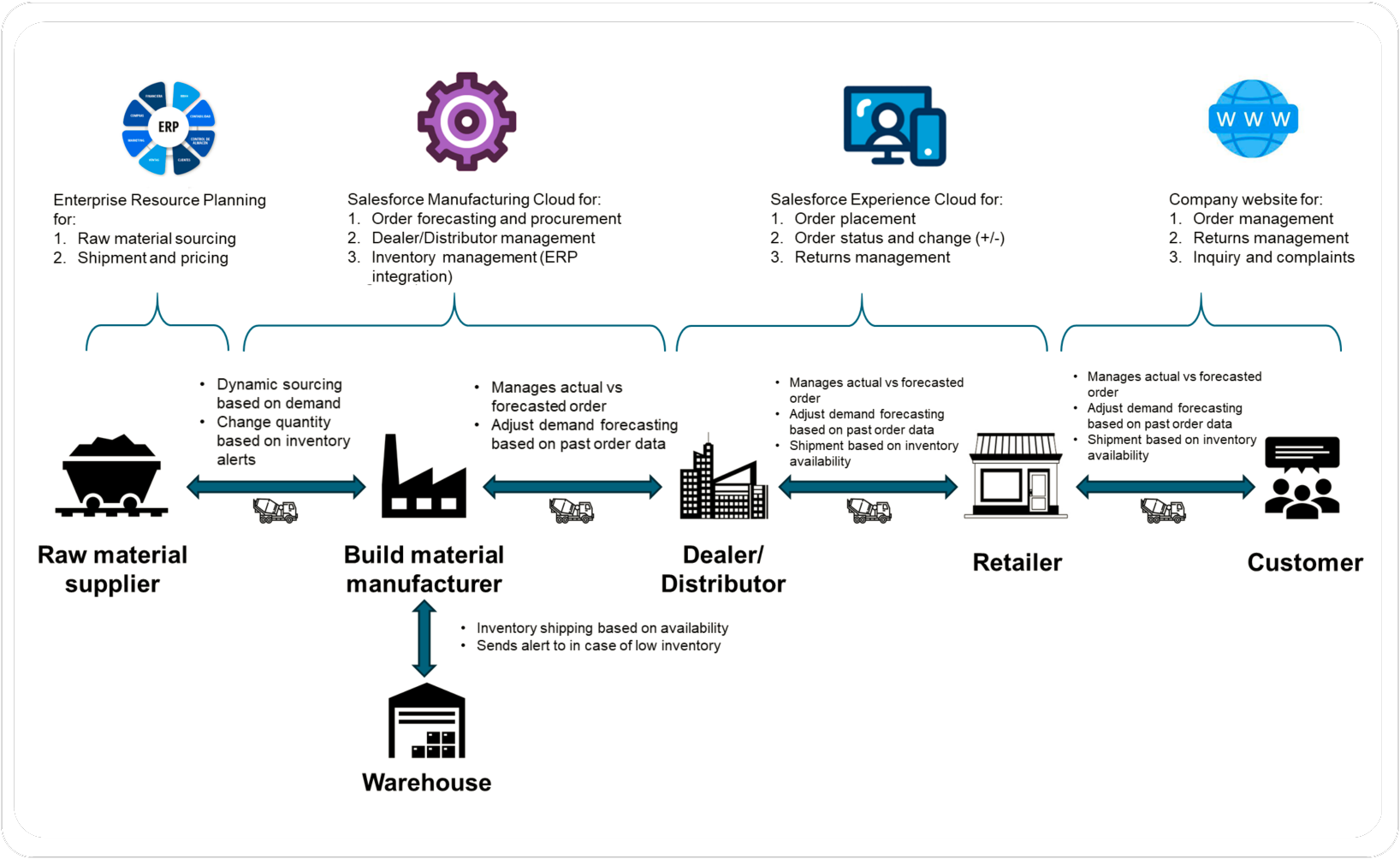

ii. Areas of improvement for accurate demand management and supply chain

Planning Process

Improving the planning process in the building material industry requires careful consideration of various factors, including demand forecasting, production scheduling, inventory management, supply chain optimization and collaboration with stakeholders.

Production Scheduling

Smart Planning Capacity by leveraging AI models that predicts demand variability, prioritize production orders and optimize production schedules.

Demand

Forecasting

Invest in advanced demand forecasting technologies to accurately predict future demand by utilizing historical sales data, market trends and customer insights.

Inventory Management

Implementing effective inventory management strategies to optimize inventory levels, reduce carrying costs, and minimize stockouts.

Supply Chain Optimization

Streamline supply chain processes and optimize logistics and distribution networks to improve efficiency, reduce lead times, and enhance responsiveness to customer needs.

Purchase Process

Improving the purchase process in the building materials industry is essential for optimizing inventory levels, reducing costs and ensuring timely availability of materials for construction projects.

Supplier Management

Smart Planning Capacity by leveraging AI models that predicts demand variability, prioritize production orders and optimize production schedules.

Strategic Sourcing

Leverage AI based sourcing tools to identify and select suppliers that offer the best value proposition in terms of quality, price, lead times and service levels.

Vendor Manager Inventory

Monitor inventory levels at customer locations and proactively replenish stock based on predefined inventory levels and demand forecasts.

Centralized Procurement

Establish centralized procurement teams to oversee purchasing activities, negotiate bulk discounts and coordinate purchasing decisions.

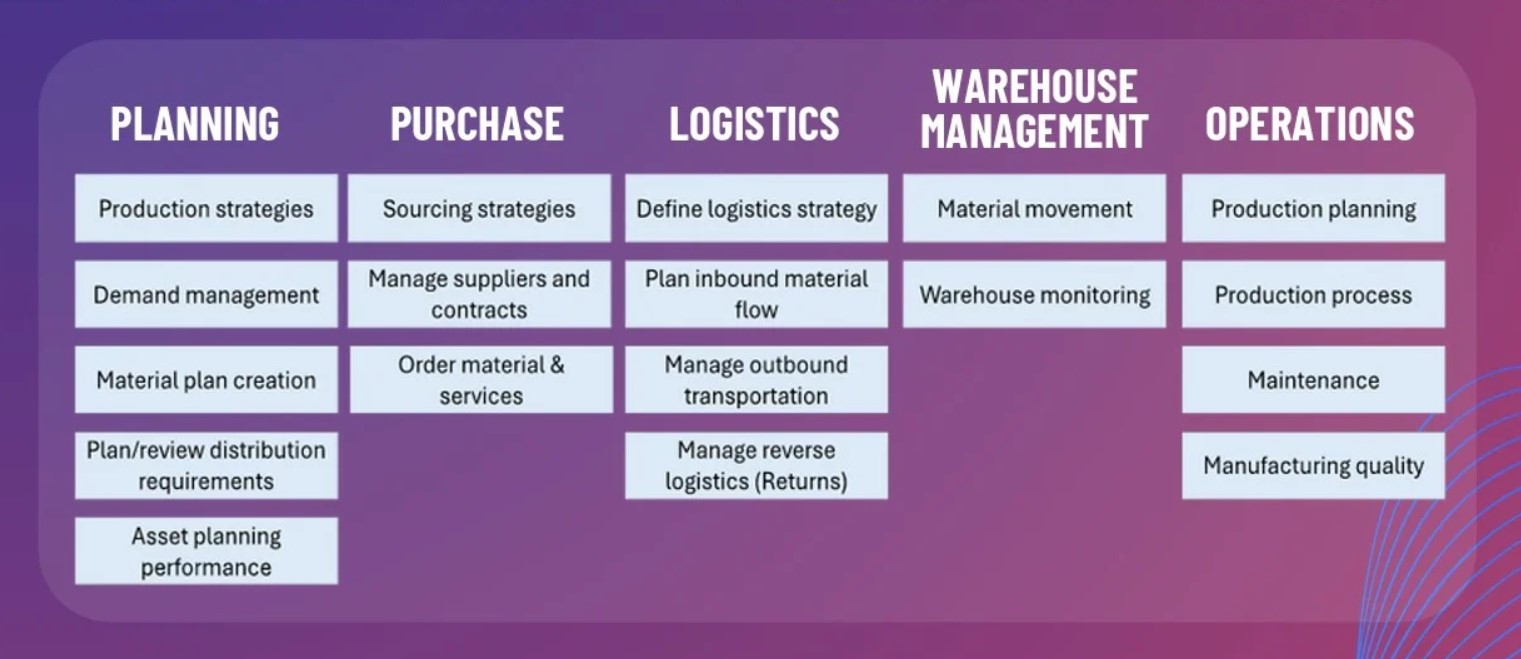

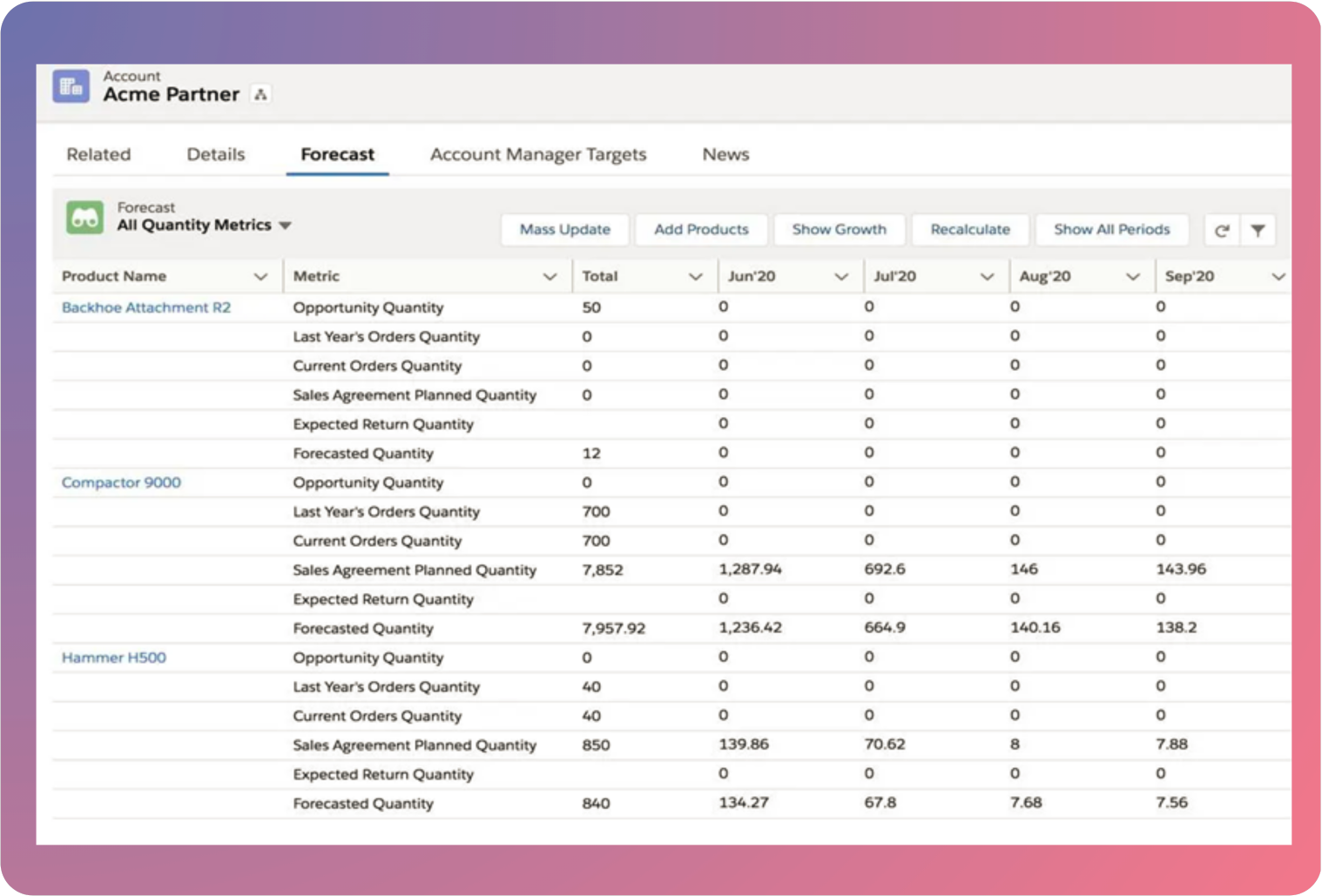

iii. How can Salesforce Manufacturing Cloud help in managing Accurate Demand Forecasting?

Account-Based Forecasting can help in accurate demand prediction by providing a holistic view of customer demand, aligning sales and forecasting processes, and leveraging customer-specific insights to improve forecast accuracy.

Here’s how Account-Based Forecasting in Salesforce can contribute to accurate demand prediction

Analyse and Predict Demand Based on Past Data

Integrate with ERP and other order management system to analysis the previous years’ actual and forecasted order data. Based on any changes in the forecasted order by a dealer/distributor, alerts can be sent to the manufacturer to change demand forecasting to avoid dead stock.

Real-Time Visibility

Provides real-time visibility into inventory levels, production capacities and sales pipelines. This real-time data allows building material manufacturers to adjust their forecasts dynamically in response to changing market conditions, unexpected demand spikes or supply chain disruptions.

Granular Customer Segmentation

By segmenting customers at the account level, organizations can tailor forecasting models and predictions to account for variations in demand patterns, preferences, and market dynamics among different customer segments.

Integrated Sales and Forecasting Data

Account-Based Forecasting integrates sales data, customer data, and forecasting data within the Salesforce platform, providing a single source of truth for sales and forecasting activities. By aligning this data organizations can ensure consistency, accuracy and timeliness in demand predictions, eliminating silos .

Overall, Account-Based Forecasting from Salesforce provides organizations with the tools, insights, and capabilities needed to generate more accurate demand predictions by leveraging customer-specific data, aligning sales and forecasting processes and applying advanced analytics and AI techniques to identify predictive indicators of future demand.

iv. Benefits of Salesforce Manucturing Cloud For building material manufactuers

Improved Forecast Accuracy

Leverage historical sales data, customer engagement and account specific variables.

Optimized inventory management

Smart inventory alerts helps to minimize carrying costs, improve inventory turnover.

Enhanced sales & operation alignment

Integrates seamlessly with ERP and other backend systems for a single customer view.

Increased customer satisfaction

Timely and accurate delivery based on customer demand leads to repeat business.